website

Hotline

Copyright © 2019 RUFONG Machinery 豫ICP备17034389号 Powered by www.300.cn

LINK

0086-371-69961188

PRODUCTS

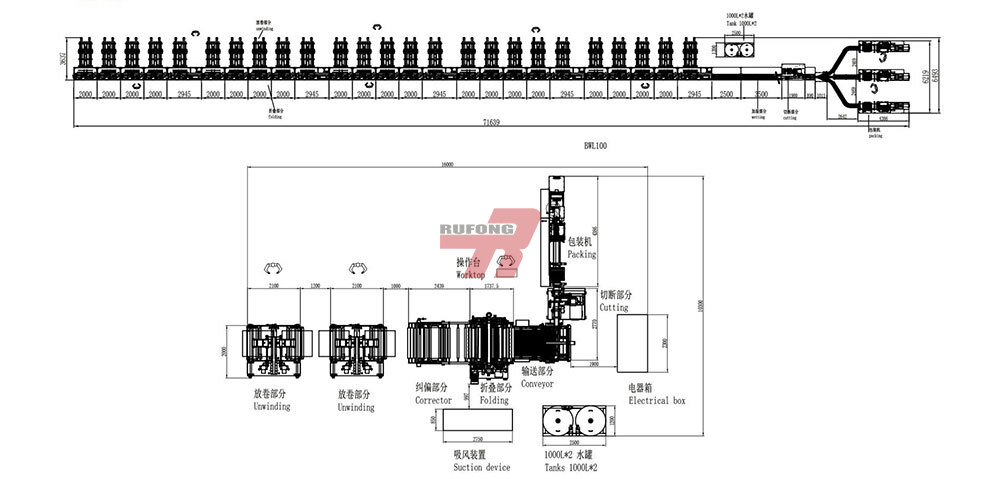

RF-BWL100

Phone

0086-371-69961188

Basic Introduction:

RF-BWL100 (80) baby wet wipe production line produces disposable household cleaning wet wipes or baby wet wipes. Enterprises need to increase their production capacity to meet their growing demands. RF-BWL100 (80) is a cost-effective solution. Full-featured servo drive, 160bags/min speed, big free-swing knife achieves wider range of cloth cutting thickness, automatic connection between cloth releasing frame and film releasing shaft reduces the time spent in replacing raw materials and thus greatly improving the work efficiency. Moreover, online inspection of cloth connectors and online removal of connecting joints ensure the quality of the product.

Features:

Control System: Multi-shaft motion controller

Drive Unit: Servo motor

Operation Interface: 10" LCD touch screen

Wet Wipe Cutting: Synchronous big free-swinging knife

Packaging: Automatic diversion, packed with two packaging machines, can link to Internet respectively

Paper Unwinding Mechanism: 100 (80) sets of paper rewinding belts

Fractional Frequency Detection: 100 (80) electric eyes achieve online detection

Fractional Frequency Traction: 5 (4) sets of dry wipe stacking traction and 2 sets of wet wipe stacking traction

Automatic Connection: The roll film connects automatically and labels convert automatically

Fractional Frequency Detection: Cloth, film and label joints are detected respectively

Metal Detection: Online metal detection

Reject Removal: Online bad connection joints removal

Flow Control: 2.5-4 times of flowmeter measurement and control

Liquid Injection Method: 100 (80) liquid tubes spray independently

Stirring Liquid Storage: Two 1,000L stainless steel stirring pots

Liquid Level Control: Electronic surveillance and automatic control

Product Size:

Wet Wipe Size: L120-250mm W90-1150mm

Unfolding Size: L120mm-250mm W150mm ~ 220mm

Packing Size: L150mm-350mm W80-120mm H20-100mm