website

Hotline

Copyright © 2019 RUFONG Machinery 豫ICP备17034389号 Powered by www.300.cn

LINK

0086-371-69961188

PRODUCTS

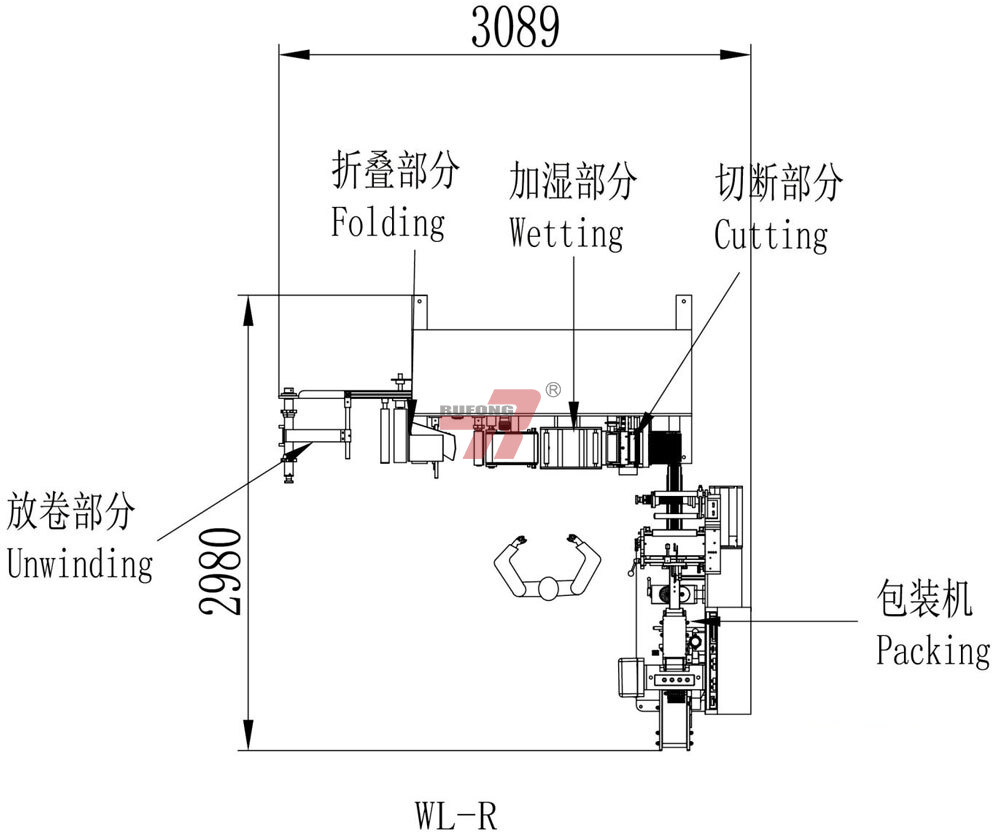

RF-WL-R

Phone

0086-371-69961188

The RF series WL-R wet tissue production line is used for the independent packaging of round-rolled wet tissue rolls for catering and aviation. Stable speed is 180 bags/min.

Production line configuration

Control drive system: PLC programmable controller, GOT operation interface, servo motor precision transmission

Unwinding and unwinding device: independent unwinding belt drive, running tension automatic detection and adjustment

Folding traction mechanism: longitudinal V-shaped folding, servo traction synchronous conveying

Rotary cutting system: synchronous cutting by roller knife, precise cutting length control, flexible and convenient cloth length adjustment

Quantitative humidification system: two sets of spray pipes, uniform humidification in the range of 2.5-4.8 times

Folding and rolling device: manipulator-guided folding, the upper belt and the lower scrubbing board are synchronized

Feeding structure of the push rod: the blanking position can be adjusted, and the push rod is equally spaced to feed materials to keep the cloth film running synchronously

Bag forming device: automatic adjustment of film tension, flexible adjustment of bag width and height

Packaging sealing and cutting device: Taiwan's Lu Feng vertical sealing technology, rotary horizontal sealing design, strong and beautiful sealing

Quality control system: the whole process of equipment operation is monitored, and the troubleshooting is automatically prompted

Security system: Fixed, movable, and enclosed protective devices comply with ISO14120:20021.